- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

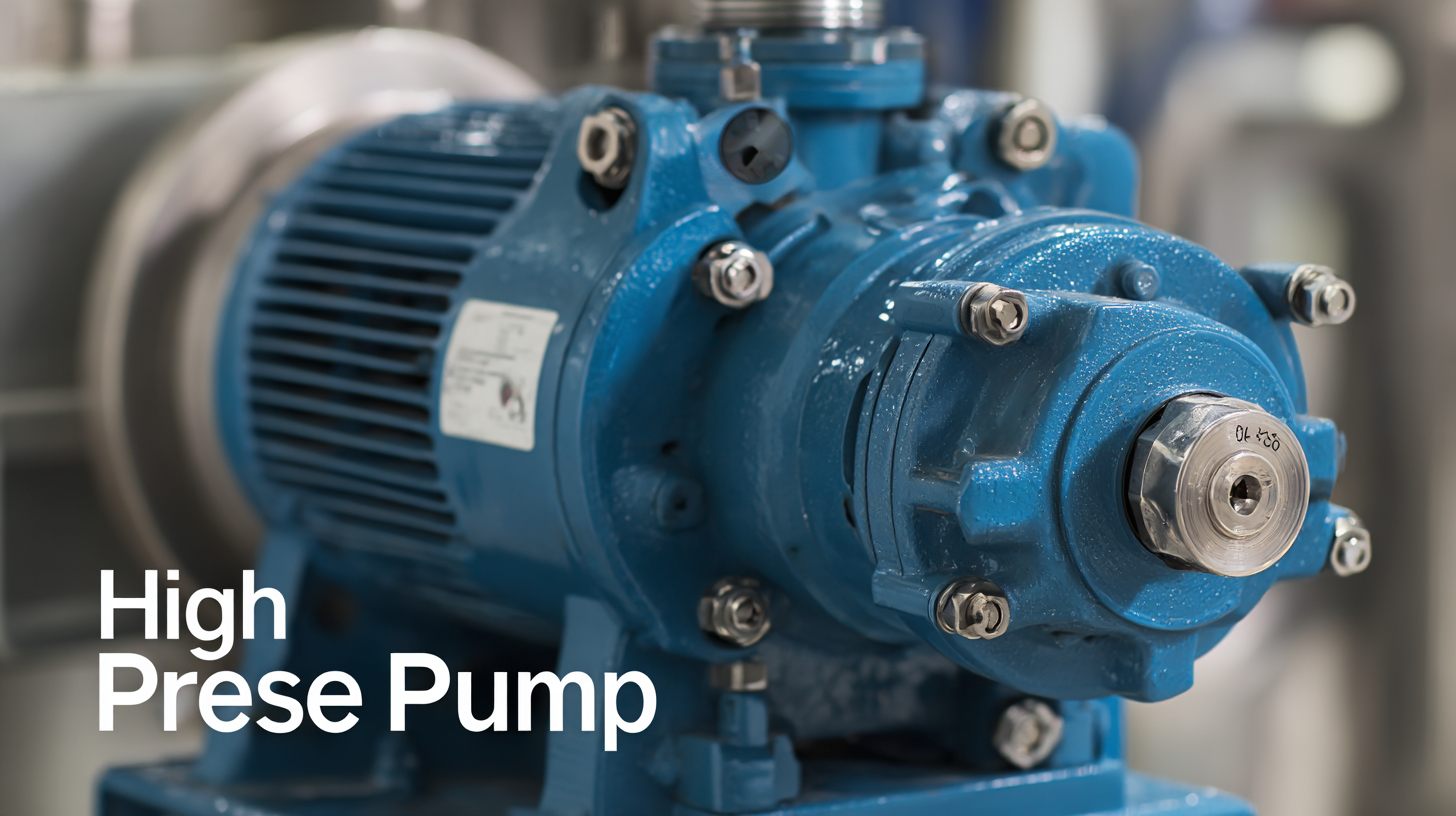

Exploring the Versatility of High Pressure Pumps Across Different Industries and Their Unique Benefits

In today's rapidly evolving industrial landscape, the versatility of high pressure pumps has garnered significant attention across various sectors. These powerful machines are not only essential for tasks requiring intense fluid movement but also serve an array of specialized applications, from cleaning and surface preparation to food processing and chemical manufacturing. By harnessing the capabilities of high pressure pumps, industries can achieve greater efficiency, increased safety, and superior results. This guide delves into the unique benefits of high pressure pumps, illustrating their critical role in enhancing productivity and innovation across multiple fields. Join us as we explore how these dynamic tools are transforming processes and driving success in diverse environments.

Innovative Applications of High Pressure Pumps in Manufacturing Processes

High pressure pumps are essential across various industries, playing a pivotal role in enhancing manufacturing processes through innovative applications. The global market for metering pumps is expected to witness significant growth, with types such as diaphragm pumps, peristaltic pumps, electromagnetic pumps, plunger pumps, and hydraulic pumps accounting for diverse operational needs. According to industry analysis, the segment of pumps with flow rates exceeding 100 liters per minute is projected to capture a substantial market share, driven by increasing demand in sectors like chemicals, pharmaceuticals, and electronics.

A notable instance of high pressure pump application is evident in the chemical industry, where magnetic drive vortex pumps are utilized for their robust sealing capabilities and stable flow rates. These pumps have gained traction in projects like the CCUS initiative, which focuses on carbon capture and storage, showcasing the industry's shift towards sustainable practices. With advancements in pump technology, manufacturers are consistently optimizing their processes, improving efficiency, and reducing operational costs, thereby reinforcing their competitive edge in the market.

Exploring the Versatility of High Pressure Pumps Across Different Industries and Their Unique Benefits

| Industry | Application | Benefits | Pressure Range (psi) |

|---|---|---|---|

| Manufacturing | Surface Cleaning | Improved Surface Preparation | 1500 - 3000 |

| Food Processing | Pasteurization | Enhanced Food Safety | 4000 - 6000 |

| Oil & Gas | Hydraulic Fracturing | Increased Resource Extraction | 3000 - 15000 |

| Construction | Concrete Pumping | Faster Construction Times | 2000 - 5000 |

| Chemical Processing | Fluid Transfer | Safe Handling of Hazardous Materials | 1000 - 8000 |

The Role of High Pressure Pumps in Environmental Protection and Sustainability

High pressure pumps play a crucial role in advancing

environmental protection and sustainability

across various industries. Their ability to operate efficiently at elevated pressures makes them indispensable in

applications such as wastewater treatment, where they facilitate the effective removal

of pollutants. According to a report by the Environmental Protection Agency, approximately 74% of

municipal wastewater treatment facilities in the U.S. utilize high pressure technology for better filtration

and chemical dosing, thus contributing to improved water quality and ecosystem preservation.

In the industrial sector, high pressure pumps are integral to processes like

ultra-high pressure water jetting, which is used for surface cleaning, material removal,

and even demolition. This method significantly reduces the need for harsh chemicals, thereby minimizing hazardous waste.

A study conducted by the International Water Jetting Association indicates that utilizing high pressure pumps

in these applications can lead to a reduction of up to 50% in environmental contaminants compared to

conventional methods. Furthermore, these pumps also enhance energy efficiency, as modern designs can achieve remarkable

performance levels, thus supporting sustainable operational practices

across various fields.

Enhancing Energy Efficiency: The Benefits of High Pressure Pumps in Various Industries

High pressure pumps have emerged as essential components across various industries, driving improvements in energy efficiency and operational effectiveness. According to a report by the U.S. Department of Energy, high-efficiency pumps can reduce energy consumption by up to 20% compared to standard pumps, resulting in significant cost savings for businesses. This enhancement is particularly noticeable in sectors like manufacturing, water treatment, and oil and gas, where precise fluid handling is crucial. For instance, in the oil and gas sector, utilizing high pressure pumps can boost productivity while minimizing waste, demonstrating their versatile applications in demanding environments.

Tip: Regular maintenance of high pressure pumps is vital to ensure optimal performance and energy efficiency. Implementing a preventive maintenance schedule can help minimize breakdowns and extend the lifespan of your equipment.

Furthermore, high pressure pumps facilitate processes such as cleaning and surface preparation in the manufacturing industry, enhancing production cycles. A study from the Hydraulic Institute indicates that advanced pump systems can lead to a 15% reduction in overall operational costs by improving system designs and reducing energy losses. As industries increasingly prioritize sustainability, choosing high pressure pumps equipped with energy-efficient technologies can significantly reduce their carbon footprint while boosting overall productivity.

Tip: Invest in advanced monitoring systems that provide real-time data on pump performance, allowing for timely adjustments that enhance energy efficiency and operational reliability.

Energy Efficiency Benefits of High Pressure Pumps Across Industries

Future Trends: Smart Technology and Automation in High Pressure Pump Systems

The integration of smart technology and automation in high-pressure pump systems is significantly shaping the future of various industries. As sectors like water treatment, oil and gas, and manufacturing continue to evolve, the adoption of advanced monitoring and control systems is becoming paramount. These intelligent solutions not only enhance operational efficiency but also improve safety and reduce maintenance costs. With real-time data analytics, operators can make informed decisions and react swiftly to any anomalies, ensuring that the systems run optimally at all times.

When considering the implementation of smart technology in high-pressure pumps, here are a few tips to keep in mind: First, ensure compatibility between existing systems and new technologies to avoid integration challenges. Secondly, invest in user training to empower your team in utilizing these advanced tools effectively. Lastly, prioritize cybersecurity measures as IoT-connected devices become more prevalent, safeguarding against potential vulnerabilities.

As automation continues to expand, high-pressure pump systems are poised to become more adaptive and responsive. Future trends indicate that machine learning and AI will further enhance predictive maintenance capabilities, allowing businesses to minimize downtime and maximize productivity. By embracing these innovations, industries can enhance their operational resilience while meeting the growing demands of an ever-changing marketplace.

Comparative Analysis: High Pressure Pumps in Food Processing vs. Chemical Industries

High pressure pumps play a crucial role in both food processing and chemical industries, each benefiting uniquely from their versatility. In food processing, high pressure processing (HPP) techniques ensure food safety and quality by significantly reducing microbial loads without the need for preservatives. This not only extends shelf life but also preserves the nutritional value and freshness of food products.

The integration of innovative pump technologies in this sector allows for efficient handling of viscous materials while ensuring compliance with stringent health regulations, ultimately contributing to a more sustainable food supply.

The integration of innovative pump technologies in this sector allows for efficient handling of viscous materials while ensuring compliance with stringent health regulations, ultimately contributing to a more sustainable food supply.

Conversely, in the chemical industry, high pressure pumps are essential for the efficient movement and processing of hazardous fluids. Their ability to withstand extreme conditions and provide precise control over fluid dynamics is paramount for safe chemical reactions and material handling. The growth of this sector is underpinned by the increasing demand for advanced materials and sustainable processes, leading to continuous innovations in pump technology. With the global market for various types of pumps, including high pressure variants, projected to grow significantly, understanding the distinct applications and advantages across these industries remains vital for fostering future developments.