- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

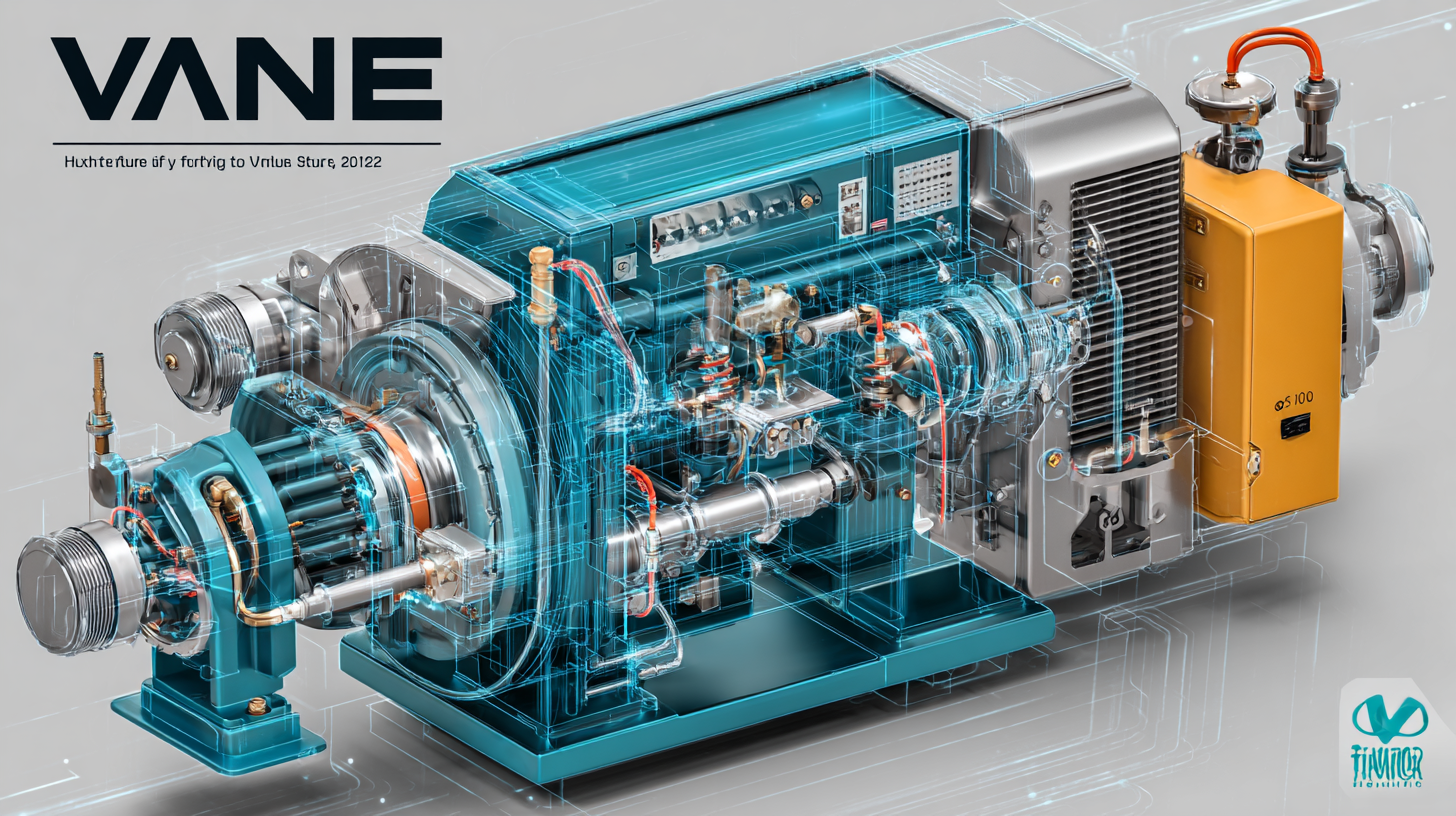

Navigating the Future of Vane Pumps in 2025 Top Technology Trends and How to Adapt Your Supply Chain

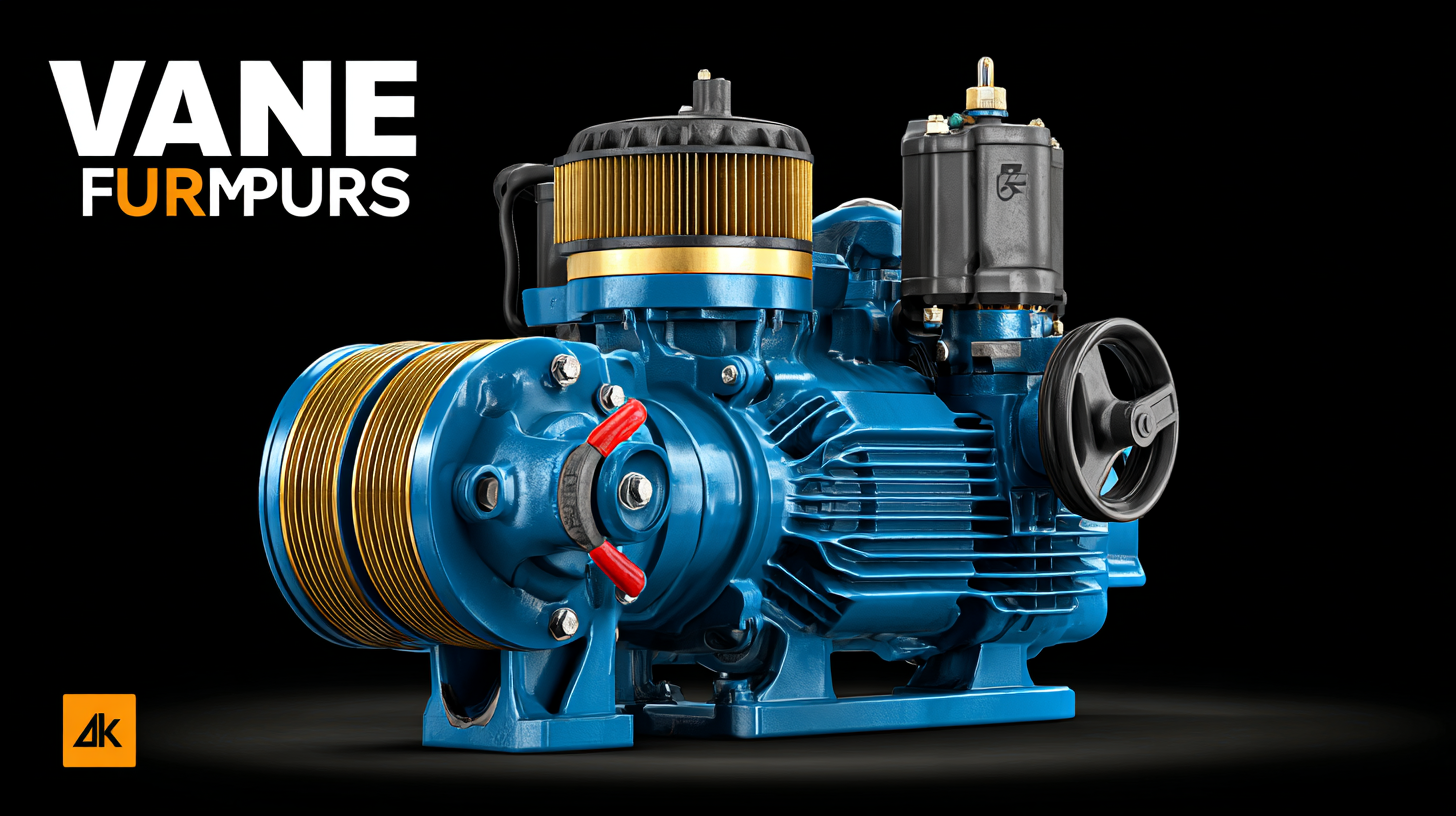

As we look ahead to 2025, the landscape of vane pumps is poised for transformative changes driven by technological advancements and evolving market demands. Vane pumps, known for their efficiency and versatility in fluid transfer applications, are at the forefront of innovation, with trends focusing on automation, smart technology integration, and sustainability. In this rapidly changing environment, supply chain adaptations will be crucial for manufacturers and distributors striving to remain competitive. This blog will explore the top technology trends shaping the future of vane pumps and provide actionable insights on how to effectively adapt your supply chain strategies to navigate these developments. By understanding these trends, stakeholders can better position themselves for success in the dynamic landscape of the vane pump industry.

Emerging Technologies Transforming Vane Pumps by 2025

As we look towards 2025, the vane pump industry is poised for a revolution driven by emerging technologies. One of the most significant trends is the integration of IoT (Internet of Things) capabilities, which allows for real-time monitoring of pump performance and efficiency. This connectivity enables operators to gather data on operating conditions, identify potential issues before they escalate, and optimize maintenance schedules. As a result, businesses can increase uptime and reduce operational costs, making IoT a game-changer for the vane pump market.

In addition to IoT, advancements in materials science are set to enhance the durability and performance of vane pumps. The development of new, high-performance polymers and coatings can significantly improve resistance to wear and corrosion, extending the lifespan of pumps in challenging environments. Furthermore, the adoption of additive manufacturing techniques is making it possible to produce bespoke components that meet specific operational requirements. By embracing these technological innovations, companies can not only adapt their supply chains but also position themselves as leaders in the evolving vane pump landscape.

Navigating the Future of Vane Pumps in 2025: Top Technology Trends and Adaptation Strategies

| Technology Trend | Impact on Vane Pumps | Adaptation Strategy | Expected Outcome |

|---|---|---|---|

| Digital Twin Technology | Improved monitoring and predictive maintenance | Invest in digital twin software | Reduced downtime and maintenance costs |

| IoT Integration | Enhanced data collection for performance analysis | Implement IoT sensors in pumps | Better operational efficiency |

| 3D Printing | Faster prototyping and customization | Adopt 3D printing technologies in production | Shorter lead times for components |

| AI and Machine Learning | Optimized performance and fault detection | Integrate AI-driven tools for analysis | Enhanced reliability and user experience |

| Eco-friendly Materials | Reduction of environmental impact | Source sustainable materials for production | Increased market competitiveness |

Sustainable Alternatives: Eco-Friendly Solutions for Vane Pump Manufacturing

As we approach 2025, the demand for sustainable manufacturing practices has become more critical than ever, especially in the realm of vane pump production. Traditional manufacturing processes often involve materials and methods that can harm the environment, leading to resource depletion and increased waste. However, the vane pump industry is beginning to embrace eco-friendly alternatives that not only minimize environmental impact but also align with global sustainability goals.

One such innovation is the use of biodegradable materials in manufacturing vane pumps. These materials, derived from renewable resources, reduce the carbon footprint and contribute to a circular economy. Furthermore, advancements in manufacturing technologies, such as additive manufacturing, allow for the creation of complex components with less material waste. By integrating these sustainable practices into their supply chains, manufacturers can secure a competitive edge while addressing consumer preferences for greener products.

Additionally, companies are investing in research and development to explore alternative energy sources for vane pumps. Utilizing solar or wind energy in the production process not only conserves fossil fuels but also positions manufacturers as leaders in the transition towards sustainable industrial practices. As the industry shifts towards these eco-friendly solutions, it becomes imperative for businesses to adapt their supply chains and stay ahead of the curve. Embracing these sustainable alternatives will not only benefit the environment but also support long-term business viability in a rapidly changing market.

Adapting Supply Chains: Strategies for Resilience in Pump Production

In the evolving landscape of vane pump production, adapting supply chains to bolster resilience is crucial for manufacturers aiming to thrive by 2025. The recent disruptions in global markets have underscored the necessity for agile supply chain strategies. One effective approach involves diversifying suppliers to reduce dependency on a single source, which can mitigate risks associated with geopolitical tensions or natural disasters. By establishing a network of reliable suppliers across various regions, companies can ensure a steady flow of materials, thus enhancing their production capacity and adaptability.

Moreover, incorporating advanced technologies into the supply chain can significantly improve operational efficiency. Implementing smart logistics solutions, such as IoT devices and AI-driven analytics, enables companies to monitor inventory levels in real-time and predict demand fluctuations with greater accuracy. This data-driven approach allows manufacturers to optimize their production schedules and minimize waste, ultimately leading to cost savings and increased responsiveness to market changes. As the industry gears up for future challenges, embracing these strategies will be essential for maintaining competitiveness and ensuring long-term sustainability in vane pump production.

Automation and IoT: Enhancing Efficiency in Vane Pump Operations

As we look toward 2025, the integration of automation and IoT technologies is set to revolutionize the operation of vane pumps. Automation streamlines processes, reducing human error and increasing precision in operations. By implementing automated control systems, manufacturers can enhance the responsiveness of vane pumps to changing operational demands. This level of control allows for real-time adjustments and optimization, ensuring that the pumps operate at peak efficiency throughout their lifecycle.

Additionally, the Internet of Things (IoT) plays a crucial role in enhancing the efficiency and reliability of vane pump operations. By equipping pumps with IoT sensors, operators can collect and analyze data regarding performance, temperature, and flow rates. This data analytics not only aids in predictive maintenance—allowing for timely interventions before failures occur—but also provides insights that can inform design improvements. Harnessing IoT ensures that businesses can not only react swiftly to issues but can also gain a competitive edge by leveraging data-driven decisions to refine their supply chain strategies.

Future Market Trends: Predictions and Opportunities for Pump Manufacturers

As we look towards 2025, the vane pump industry is poised for significant transformation, driven by emerging market trends and advancements in technology. According to recent reports, the ISO and ANSI pump market was valued at approximately $3.70631 billion in 2023, and it is projected to reach $3.849 billion by 2024, with remarkable growth expected to continue, reaching $5.207 billion by 2032. This trend indicates a Compound Annual Growth Rate (CAGR) that reflects the increasing demand for efficient and reliable pumping solutions across various sectors.

In parallel, the molecular pump market is witnessing substantial expansion, with notable insights highlighting its growth trajectory from 2025 to 2033. The market is segmented by types, including molecular drag pumps and turbo molecular pumps, catering to diverse applications such as analysis, nanotechnology tools, and industrial vacuum processing. This growth presents opportunities for pump manufacturers to innovate and adapt their supply chains to meet the evolving needs of their clients. Embracing these trends will not only position companies at the forefront of the industry but also enhance their competitiveness in a rapidly changing market landscape.