- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Unlocking the Power of High Pressure Pumps: Essential Insights for Industrial Applications

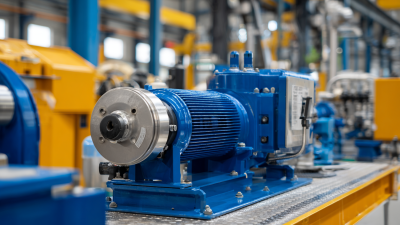

In the realm of industrial applications, the significance of High Pressure Pumps cannot be overstated. These robust systems, typically operating at pressures exceeding 10,000 psi, are crucial in various sectors, including oil and gas, chemical processing, and water treatment. According to a report by MarketsandMarkets, the global high-pressure pump market is projected to grow from USD 3.5 billion in 2020 to USD 4.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.7%. This surge is driven by increasing demand for efficient fluid handling solutions and the need for automation and precision in processes. Understanding the intricacies of High Pressure Pumps—ranging from their operational principles to selection criteria and maintenance best practices—can significantly enhance productivity and reduce operational costs in industrial settings. This article aims to provide essential insights on unlocking the full potential of High Pressure Pumps for varied applications.

The Role of High Pressure Pumps in Various Industries

High pressure pumps are vital components in numerous industrial sectors, playing a crucial role in applications ranging from water jet cutting to oil and gas extraction. According to a report by Allied Market Research, the global high pressure pump market is projected to reach $4.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.9%. This growth is driven primarily by advancements in pump technology and increasing demand for high-pressure systems in manufacturing processes.

In the oil and gas industry, for example, high pressure pumps are essential for hydraulic fracturing, a technique that allows for the extraction of oil and gas from underground formations. According to the U.S. Energy Information Administration, hydraulic fracturing technologies contributed to about 73% of the total U.S. crude oil production in 2020, emphasizing the critical nature of these pumps in energy production. Additionally, in the manufacturing sector, high pressure pumps are employed in cleaning and washing processes, which are imperative for maintaining equipment and ensuring operational efficiency. As industries continue to evolve, the significance of high pressure pumps in enhancing productivity and achieving sustainable practices cannot be overstated.

Key Features to Look for in High Pressure Pumps

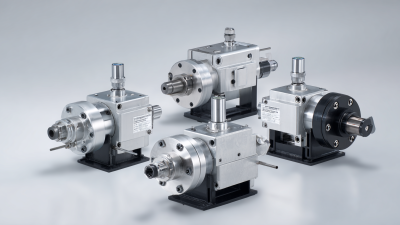

When selecting high pressure pumps for industrial applications, certain key features stand out as critical factors that can significantly affect performance and efficiency.

First and foremost, the pump's materials of construction are crucial.

Pumps that are constructed from corrosion-resistant materials, such as stainless steel or special alloys, ensure durability and longevity, especially in harsh environments.

This is particularly important for applications involving aggressive fluids and high temperatures, where standard materials may quickly degrade.

Another essential feature to consider is the pump's flow rate and pressure rating.

Industrial applications often require specific flow rates and high pressures to meet operational requirements.

It is vital to choose a pump that not only meets but exceeds these needs to ensure optimal performance and prevent failures during peak operations.

Additionally, the pump's efficiency can greatly influence operational costs, so looking for designs that minimize energy consumption while maximizing output is essential.

Properly assessing these features will lead to selecting the most suitable high pressure pump for your specific industrial requirements.

Best Practices for Maintaining High Pressure Pumps

High pressure pumps are crucial in various industrial applications, delivering fluids at elevated pressures for processes such as concrete placing, water jet cutting, and chemical injection. To ensure their efficient operation and longevity, adhering to best practices in maintenance is essential. Regular inspection of components such as seals, valves, and filters can prevent unexpected failures and optimize performance. Implementing a routine maintenance schedule, including checking for wear and tear, is vital to catch potential issues before they escalate.

Another key practice is to maintain the correct operating parameters, such as temperature and flow rate. Pumps operating at inappropriate conditions can suffer from reduced efficiency and increased wear. Monitoring vibrations and sounds during operation can also provide early warnings of mechanical issues. Additionally, ensuring proper lubrication of moving parts will reduce friction and heat, which can lead to longer service life and reliability. By following these best practices, industries can unlock the full potential of high pressure pumps, maximizing productivity and minimizing downtime.

Unlocking the Power of High Pressure Pumps: Essential Insights for Industrial Applications - Best Practices for Maintaining High Pressure Pumps

| Parameter | Description | Importance | Maintenance Frequency |

|---|---|---|---|

| Flow Rate | The volume of fluid the pump can deliver per unit time. | Ensures system efficiency and proper operation. | Monthly |

| Pressure Rating | The maximum pressure the pump can safely handle. | Critical for safety and preventing equipment failure. | Quarterly |

| Seal Condition | The integrity of seals to prevent leaks. | Prevents downtime and product loss. | Biannually |

| Vibration Levels | The amount of vibration during operation. | Indicates mechanical issues that may arise. | Monthly |

| Fluid Quality | The cleanliness and compatibility of the fluid used. | Ensures longevity and efficiency of the pump. | Ongoing |

Innovative Technologies in High Pressure Pump Design

Innovative technologies in high pressure pump design have significantly transformed industrial applications, enhancing efficiency and performance. Modern pumps utilize advanced materials and engineering techniques, allowing them to operate at higher pressures without compromising reliability. The evolution of computational fluid dynamics (CFD) has enabled engineers to optimize pump designs for reduced energy consumption and improved flow rates. This shift not only minimizes operational costs but also contributes to a more sustainable industrial ecosystem.

Furthermore, the integration of smart technologies into high pressure pumps has introduced features such as real-time monitoring and predictive maintenance. These innovations allow for better management of pump systems, reducing downtime and extending the lifecycle of equipment. The incorporation of IoT devices enables users to gather critical data, leading to informed decisions regarding maintenance and operational efficiency. As these technologies continue to develop, the potential applications of high pressure pumps are expanding, positioning them at the forefront of industrial innovation.

Common Industrial Applications and Their Pumping Needs

High pressure pumps play a vital role in various industrial applications, catering to specific pumping needs that are critical for operational efficiency. In sectors such as oil and gas, the demand for high pressure pumps has surged, with the market projected to reach approximately $35 billion by 2025, growing at a CAGR of around 5.5% (Source: Market Research Future). These pumps are essential for tasks such as hydraulic fracturing, where they deliver high pressure water to access oil and gas reserves locked in subterranean formations, highlighting their importance in energy extraction processes.

In the manufacturing sector, high pressure pumps facilitate processes such as metal fabrication and surface preparation. According to a report by Grand View Research, the global high pressure pump market in manufacturing is expected to exceed $12 billion by 2026. The pumps are integral for high-pressure washing systems, where they effectively remove contaminants from surfaces, ensuring product integrity and quality. Furthermore, in the field of chemical processing, these pumps are utilized for transferring corrosive materials under high pressure, necessitating the use of specially designed pumps to withstand harsh conditions. The diverse applications underscore the versatility and significance of high pressure pumps across multiple industries.

Related Posts

-

7 Reasons Why the Best High Pressure Pump is Essential for Your Industrial Operations

-

Exploring the Versatility of High Pressure Pumps Across Different Industries and Their Unique Benefits

-

10 Top High Pressure Pump Innovations Transforming Industrial Efficiency in 2023

-

World-Class Pump Manufacturing: China's Pride in Global Exports

-

Unlocking Efficiency: The Advantages of Choosing the Best Gear Pumps for Your Business

-

Navigating Global Standards for Best Pressure Pumps Compliance and Import Certification Guide