- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Exploring Innovative Alternatives to Best Piston Pump for Enhanced Efficiency and Performance

In the pursuit of enhanced efficiency and performance, industries are increasingly exploring innovative alternatives to traditional piston pumps. Piston pumps have long been revered for their reliability and effectiveness in various applications, but the maintenance costs and after-sales service have raised concerns among manufacturers. According to a recent report from the Global Pump Market Analysis, the operational costs associated with piston pumps can account for up to 30% of total lifetime expenses due to their complex maintenance requirements. As industries become more cost-conscious and strive for sustainable solutions, there is a pressing need to evaluate new technologies that can potentially offer superior performance while reducing overall maintenance burdens. By addressing these challenges, companies can benefit not only from improved performance but also from reduced operational downtime and lower repair costs, ultimately leading to a more competitive edge in the market.

Innovative Technologies Revolutionizing Piston Pump Design for Global Manufacturing

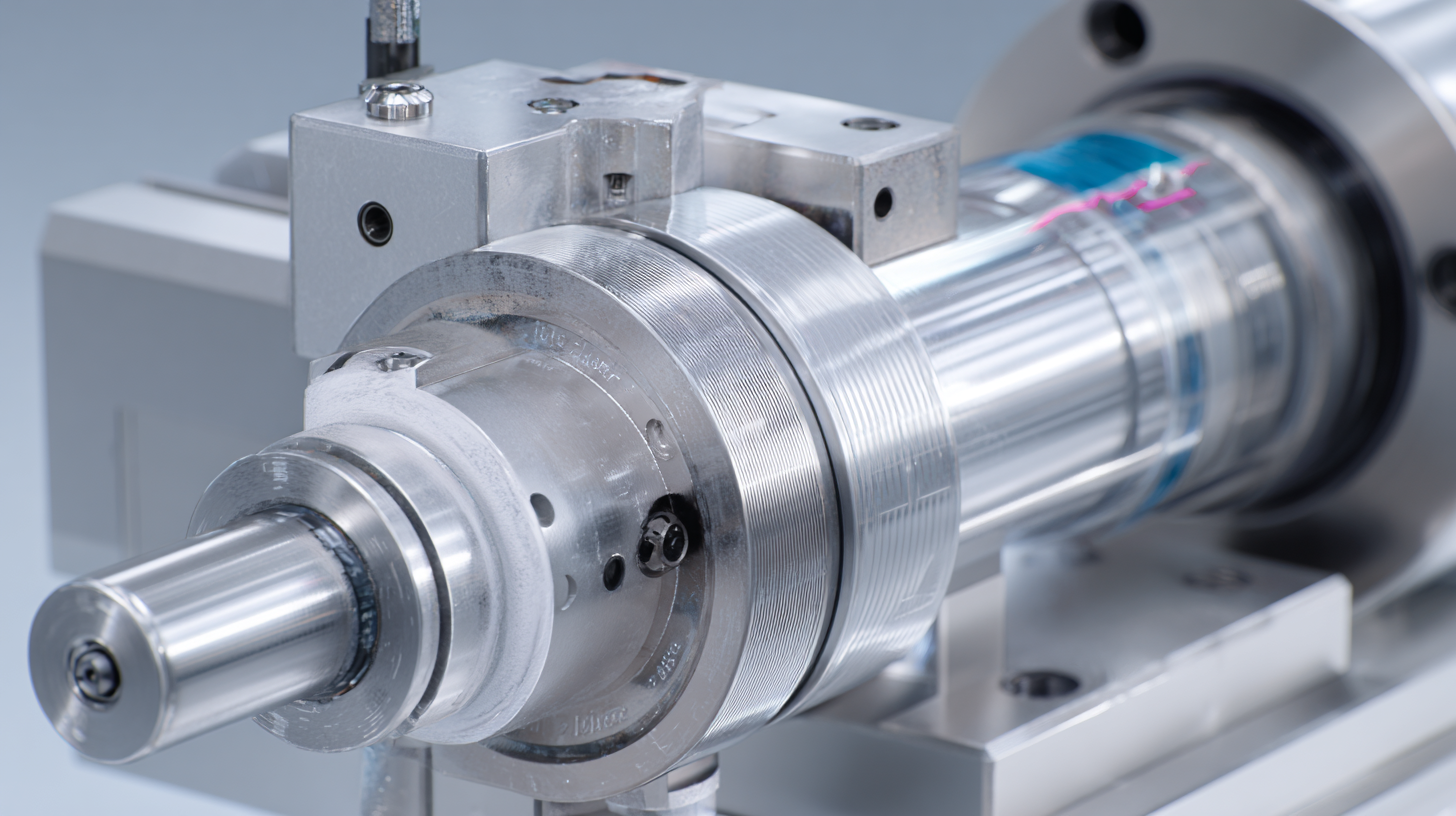

The landscape of hydraulic systems is undergoing a significant transformation as innovative technologies redefine piston pump design. The integration of modern advancements is vital for enhancing efficiency and performance in global manufacturing. As companies seek to improve the efficiency of hydraulic presses, new technology developments are becoming paramount. From advanced materials to smart control systems, the new-age piston pumps are addressing the challenges faced by industries while minimizing energy consumption and maximizing output.

In the construction equipment sector, manufacturers are increasingly prioritizing electrification and automation in their designs. As they embrace these key elements, the evolution of hydraulic systems takes center stage, enabling lighter, more efficient machinery that can withstand the demands of modern construction. Industry leaders are recognizing the importance of sustainable practices and are implementing these transformative technologies to stay competitive and responsive to market needs. As a result, the hydraulic pumps market is expected to see substantial growth, reflecting a robust movement towards innovation and ecological responsibility in manufacturing sectors worldwide.

Key Features to Consider When Choosing High-Performance Piston Pumps for Export

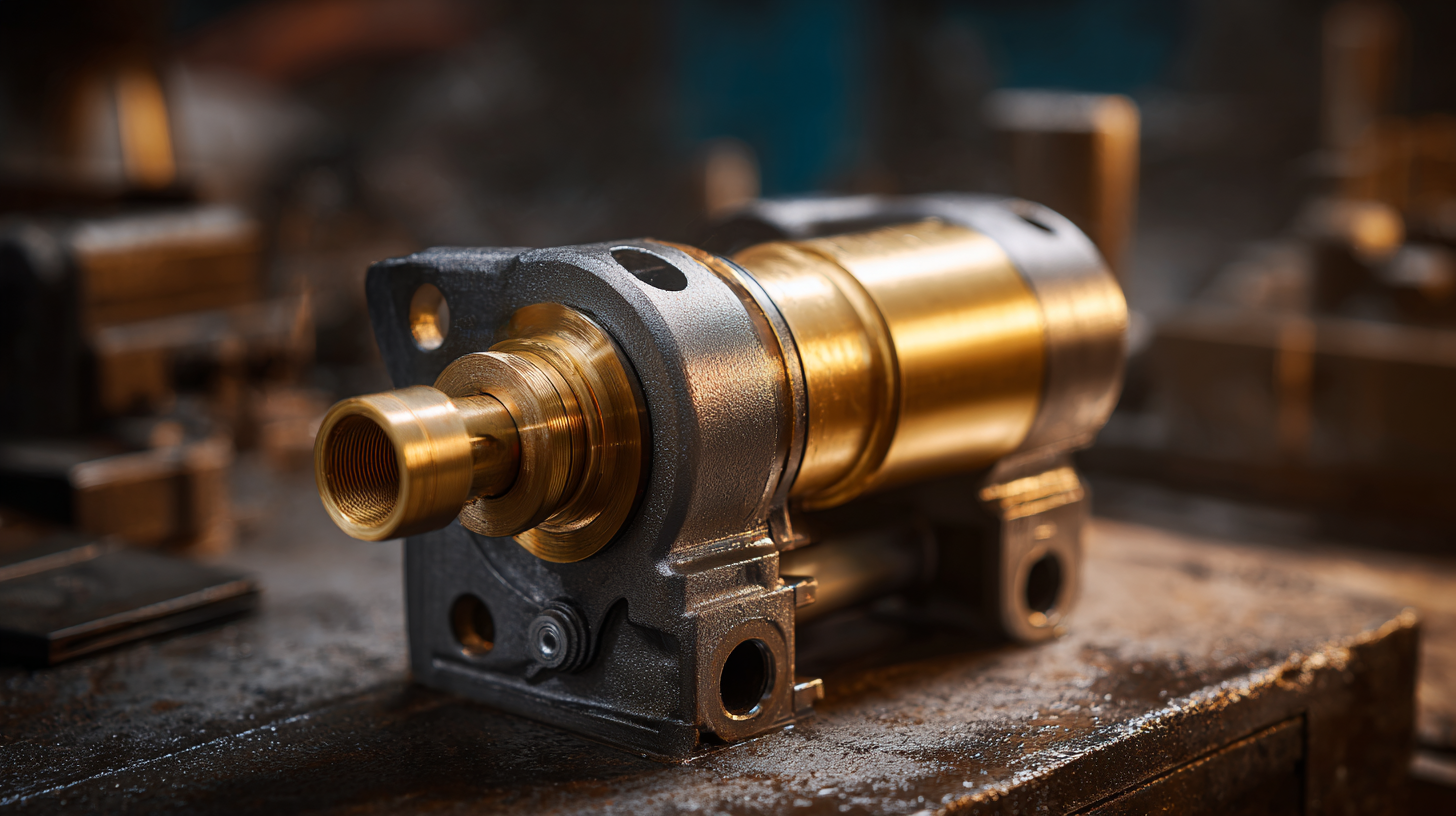

When selecting high-performance piston pumps for export, several key features must be prioritized to enhance efficiency and performance. First and foremost, the material composition of the pump is crucial. Durable materials that resist wear and corrosion can significantly extend the pump's operational lifespan, especially in demanding industrial environments. Additionally, compatibility with various fluids, including corrosive substances, should be considered to ensure the pump’s versatility across different applications.

Moreover, the design and engineering of the piston pump play a vital role in its performance. Look for pumps with innovative designs that facilitate smoother flow and reduce energy consumption. Features such as adjustable stroke lengths and variable speed controls can enhance operational efficiency by allowing customization based on specific operational needs. Furthermore, reliability in pressure regulation and noise reduction technologies can lead to a more efficient and quieter operation, which is particularly beneficial in settings where noise pollution is a concern. By focusing on these features, businesses can ensure they select piston pumps that not only meet but exceed performance expectations in their export ventures.

Efficiency Comparison of Piston Pumps

Comparative Analysis of Traditional vs. Modern Piston Pump Solutions in Industry

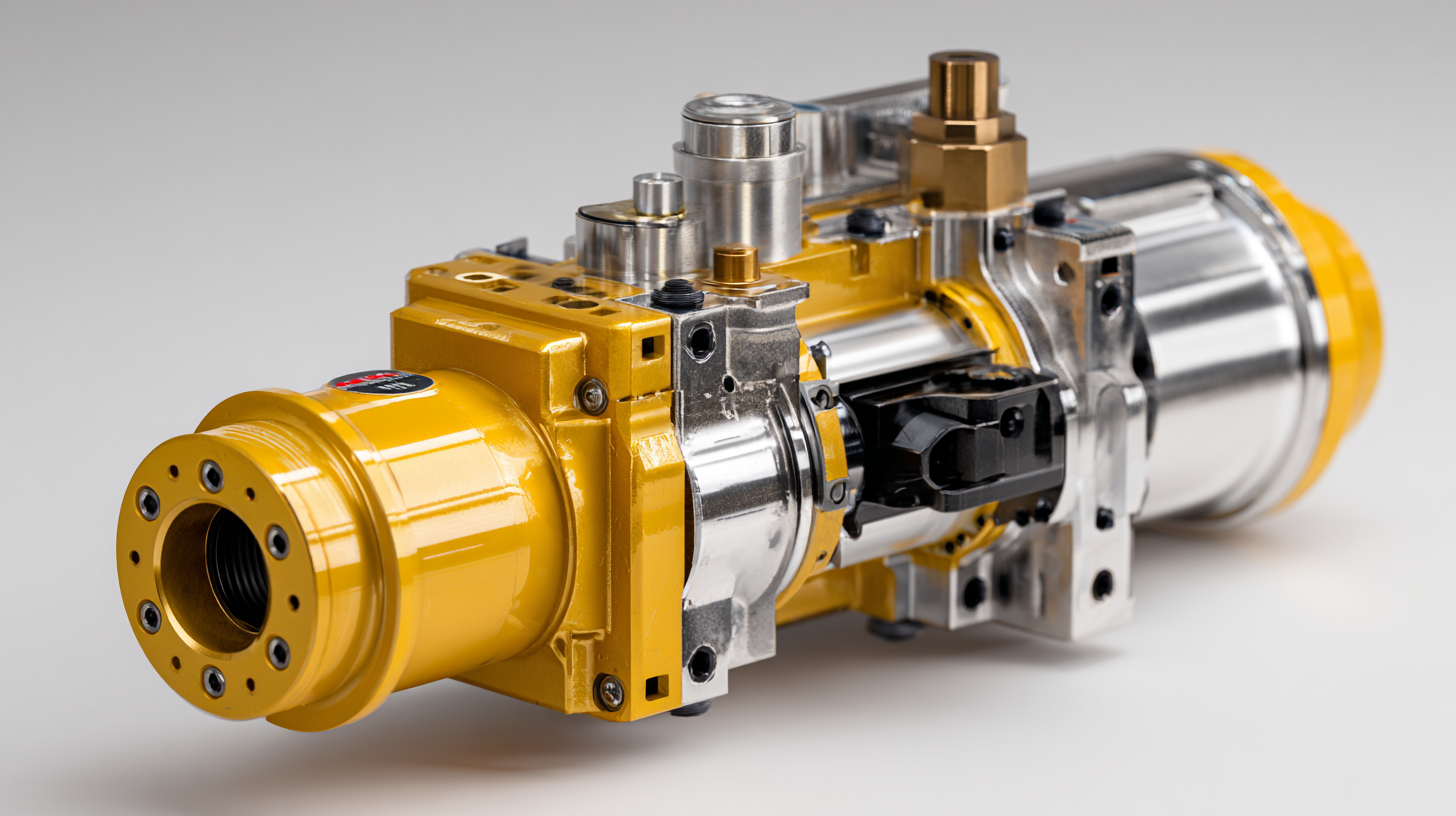

In the ever-evolving landscape of industrial machinery, piston pumps have undergone significant transformations from their traditional counterparts to modern alternatives. Traditional piston pumps, known for their simplicity and reliability, still hold a strong foothold in many industries. They typically feature a straightforward design that allows for easy maintenance and familiar operational processes. However, challenges such as energy inefficiency, limited flow rates, and environmental concerns have propelled the search for innovative solutions that can outperform these conventional systems.

Modern piston pump solutions, driven by advanced engineering and technology, offer enhanced efficiency and adaptability. Companies are now leveraging materials like lightweight composites and smart technologies to optimize performance. These innovations not only increase fluid delivery rates but also reduce energy consumption, leading to lower operational costs and a smaller environmental footprint. Additionally, features such as variable speed drives and predictive maintenance capabilities allow for greater customization and improved reliability, making these pumps a worthy consideration for industries seeking to maximize productivity and sustainability.

Through a comparative lens, it’s clear that while , modern innovations may well redefine industry standards for efficiency and performance.

Sustainability Trends Driving Piston Pump Innovations and Global Market Impact

In recent years, sustainability has become a driving force behind innovations in piston pump technology, significantly influencing the global market. As industries increasingly prioritize eco-friendly practices, manufacturers are compelled to redesign traditional piston pumps to reduce energy consumption and minimize waste. This shift not only enhances operational efficiency but also aligns with a growing consumer demand for environmentally responsible products.

One innovative approach involves the integration of advanced materials and smart technology into piston pump designs. These enhancements lead to improved durability and adaptability in various applications, ensuring that pumps can operate effectively in demanding environments. Additionally, manufacturers are focusing on modular designs, making it easier to upgrade components without replacing the entire system, thereby reducing environmental impact.

Tip: When selecting a piston pump, consider the materials used in construction; those that offer better resistance to wear and corrosion can significantly extend the lifespan of the pump.

Another trend is the rise of digital monitoring systems that allow for real-time performance analysis. By leveraging data analytics, companies can optimize their pump operations, forecast maintenance needs, and reduce downtime—ultimately contributing to a more sustainable approach to industrial processes.

Tip: Implement predictive maintenance strategies to identify potential issues before they escalate, ensuring maximum efficiency and longevity of your pump investment.

Case Studies: Successful Implementations of Alternative Piston Pump Technologies in Factories

In recent years, industries have increasingly explored innovative alternatives to traditional piston pump technologies to enhance efficiency and performance. A compelling case study to consider is the innovative implementation by a robotics and AIoT technology-focused company, which developed a comprehensive SaaS platform to optimize automation in manufacturing environments.

Leveraging cloud solutions, the company demonstrated how integrating advanced data analytics with traditional pumping systems can lead to increased operational efficiency and reduced downtime.

Moreover, another notable example is in the pharmaceutical sector, where a major player utilized advanced computing solutions to drive research while minimizing environmental impact. This approach not only streamlined their production processes but also emphasized the importance of sustainable practices in manufacturing.

Reports indicate that companies adopting such innovative technologies have recorded efficiency improvements ranging from 15% to 25%, underscoring the significant benefits of transitioning away from conventional methods. These case studies illustrate the pivotal role of alternative piston pump technologies in driving industrial transformation and sustainability efforts.

Moreover, another notable example is in the pharmaceutical sector, where a major player utilized advanced computing solutions to drive research while minimizing environmental impact. This approach not only streamlined their production processes but also emphasized the importance of sustainable practices in manufacturing.

Reports indicate that companies adopting such innovative technologies have recorded efficiency improvements ranging from 15% to 25%, underscoring the significant benefits of transitioning away from conventional methods. These case studies illustrate the pivotal role of alternative piston pump technologies in driving industrial transformation and sustainability efforts.