- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Ultimate Guide to Comparing the Best Hydraulic Vane Pumps for Global Buyers

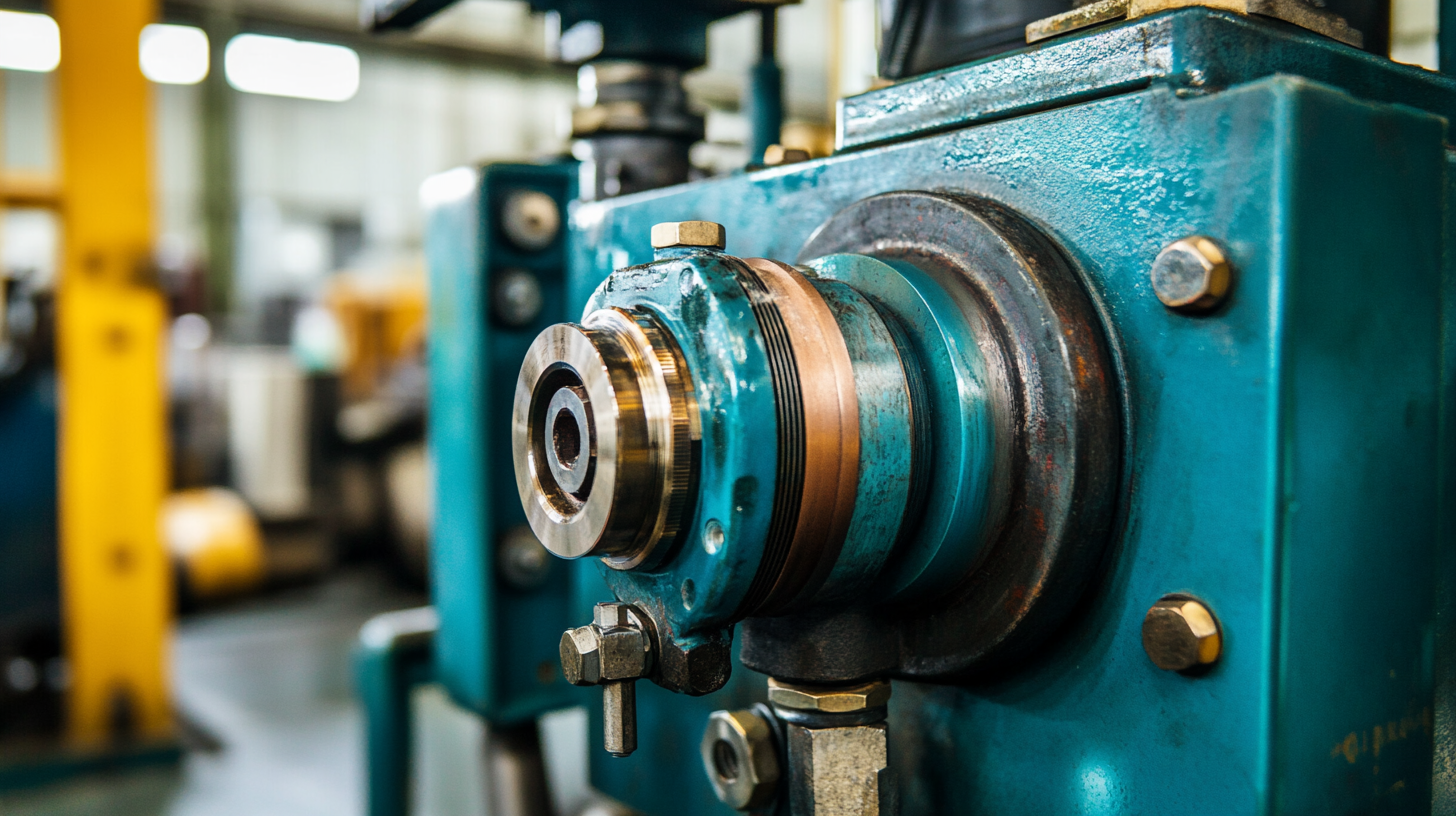

In the dynamic landscape of industrial machinery, the Hydraulic Vane Pump stands out as a pivotal component in various applications, from construction to manufacturing. According to a recent market report by Research and Markets, the global hydraulic pump market is projected to reach $14.3 billion by 2026, with hydraulic vane pumps increasingly favored for their efficiency and reliability. As global buyers seek the best options for their specific needs, understanding the comparative advantages and performance metrics of these pumps becomes crucial. This ultimate guide aims to equip buyers with essential strategies for evaluating hydraulic vane pumps, ensuring that they make informed decisions in a competitive marketplace.

By leveraging expert insights and industry data, this guide will help you navigate the complexities of selecting the right hydraulic vane pump for your applications, maximizing both performance and investment.

Understanding Hydraulic Vane Pumps: Principles and Benefits

Hydraulic vane pumps are essential components in today's fluid power applications, offering a reliable solution for various industrial processes. Unlike gear or piston pumps, vane pumps utilize a rotating mechanism with sliding vanes that create pressure differences to facilitate fluid movement. According to a report by MarketsandMarkets, the hydraulic pump market is projected to reach USD 18.7 billion by 2024, with a significant portion attributed to the growing demand for vane pumps in sectors like construction, agriculture, and manufacturing. Their versatility allows hydraulic vane pumps to operate effectively across a wide range of viscosity levels, making them suitable for both light and heavy-duty applications.

The inherent design of hydraulic vane pumps provides several benefits, including higher efficiency and smoother operation compared to traditional hydraulic pumps. Industry experts note that they can achieve efficiencies exceeding 90%, significantly reducing energy consumption and operational costs. Additionally, their compact size and lightweight nature enable easier installation and maintenance, which is particularly beneficial in space-constrained environments. The flexibility for variable displacement also allows for more precise control over flow rates, further enhancing their utility in sophisticated hydraulic systems. As enterprises aim for greater efficiency and sustainability, the adoption of hydraulic vane pumps is expected to increase across various sectors.

Key Features to Consider When Choosing Hydraulic Vane Pumps

When selecting hydraulic vane pumps, buyers must consider several key features that can significantly impact performance and efficiency. One of the primary factors is the pump's displacement, as it directly affects the flow rate and pressure capabilities. According to recent industry reports, pumps with adjustable displacement often provide improved efficiency, allowing for better control over fluid delivery in variable applications. Additionally, the construction material of the pump can influence durability and resistance to wear. For instance, pumps made from high-grade aluminum or cast iron often exhibit superior longevity in harsh environments.

Tip: Always assess the operating environment and fluid characteristics before choosing a pump, as specific applications may require special materials or designs to prevent premature failure.

Another critical feature to examine is the efficiency rating of the pump, typically measured by its volumetric and mechanical efficiency. A study by the Hydraulic Institute underscores that pumps with higher efficiency ratings often translate into lower energy consumption and reduced operational costs over time. Moreover, the pump's noise levels should not be overlooked; low-noise models can improve workplace comfort and comply with regulatory standards in residential or sensitive areas.

Tip: Refer to efficiency charts provided by manufacturers to compare models effectively, ensuring you select a pump that aligns with your operational needs without compromising on performance.

Comparison of Key Features of Popular Hydraulic Vane Pumps

Top Brands and Models of Hydraulic Vane Pumps for Global Buyers

When it comes to hydraulic vane pumps, global buyers are presented with a plethora of options, each tailored to specific industrial needs. Leading the market are renowned brands like Parker, Eaton, and Bosch Rexroth, each offering a unique blend of performance, reliability, and innovation. Parker’s hydraulic vane pumps are celebrated for their robust construction and efficiency, making them ideal for heavy-duty applications. Meanwhile, Eaton’s models are known for their advanced technology that enhances energy conservation, positioning them as a favorite in various sectors, from automotive to manufacturing.

Another noteworthy contender is Bosch Rexroth, whose hydraulic vane pumps stand out for their versatility and compact design. These pumps are engineered to excel in both high and low-pressure environments, thus catering to a wide range of machinery requirements. Global buyers must consider factors such as flow rates, pressure ratings, and compatibility with existing systems when choosing the right model. With the top brands offering distinct advantages, selecting the right hydraulic vane pump is crucial for optimizing operational efficiency and achieving long-term reliability in demanding applications.

Ultimate Guide to Comparing the Best Hydraulic Vane Pumps for Global Buyers

| Model | Flow Rate (L/min) | Pressure (Bar) | Efficiency (%) | Weight (kg) | Price ($) |

|---|---|---|---|---|---|

| Model A | 45 | 210 | 92 | 15 | 1500 |

| Model B | 60 | 230 | 89 | 18 | 1750 |

| Model C | 50 | 200 | 85 | 20 | 1800 |

| Model D | 70 | 250 | 90 | 22 | 2000 |

| Model E | 55 | 220 | 91 | 19 | 1600 |

Performance Metrics: How to Evaluate Hydraulic Vane Pumps Effectively

When evaluating hydraulic vane pumps, it is essential to consider key performance metrics that effectively indicate their suitability for various applications. According to a report by MarketsandMarkets, the hydraulic pump market is projected to reach USD 29.7 billion by 2025, with the demand for hydraulic vane pumps experiencing significant growth due to their high efficiency and reliability. Performance metrics such as flow rate, pressure, and volumetric efficiency directly impact the operational effectiveness of these pumps, making them critical factors in the purchasing decision.

Flow rate, typically measured in liters per minute (L/min), is crucial for understanding how much fluid the pump can move within a specific timeframe. A pump with a high flow rate can significantly increase productivity in hydraulic systems. In addition to flow rate, pressure ratings, measured in bar or psi, determine the pump's capability to handle the demands of various industrial applications. A study by Research and Markets emphasizes that volumetric efficiency—usually ranging from 90% to 95% for top-performing hydraulic vane pumps—plays a pivotal role in minimizing energy losses and optimizing overall system performance. By closely analyzing these metrics, global buyers can confidently select the most effective hydraulic vane pump for their operational needs.

Maintenance Tips for Longevity and Efficiency of Hydraulic Vane Pumps

Hydraulic vane pumps are critical components in various industrial applications, offering reliable performance when maintained properly.

Regular maintenance is essential for ensuring longevity and efficiency, with studies indicating that a well-maintained hydraulic vane pump can last up to 25% longer than one that is neglected.

One of the most important maintenance practices is routine oil changes, as contaminated oil can lead to component wear and reduced efficiency.

Manufacturers recommend changing the hydraulic fluid every 1,000 to 2,000 operating hours, depending on the specific application and operating conditions.

Hydraulic vane pumps are critical components in various industrial applications, offering reliable performance when maintained properly.

Regular maintenance is essential for ensuring longevity and efficiency, with studies indicating that a well-maintained hydraulic vane pump can last up to 25% longer than one that is neglected.

One of the most important maintenance practices is routine oil changes, as contaminated oil can lead to component wear and reduced efficiency.

Manufacturers recommend changing the hydraulic fluid every 1,000 to 2,000 operating hours, depending on the specific application and operating conditions.

Another key aspect of maintenance involves monitoring the pump's operating temperature and pressure. Excessive heat can cause the vanes to wear prematurely, while pressure fluctuations can indicate underlying issues that may lead to pump failure if not addressed.

According to a report by the Hydraulic Institute, approximately 70% of hydraulic system failures are related to poor maintenance practices.

By regularly inspecting seals, checking for leaks, and ensuring that filtration systems are functioning effectively, operators can significantly improve the reliability of their hydraulic vane pumps and prevent unexpected downtime,

which in turn boosts overall productivity.