- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

5 Best Practices for Choosing Hydraulic Pumps for Your Business

In the ever-evolving landscape of industrial machinery, selecting the right hydraulic pumps is crucial for optimizing operational efficiency and ensuring reliability. According to a report by Grand View Research, the global hydraulic pumps market was valued at over $10 billion in 2022 and is projected to grow significantly due to the increasing demand across various sectors, including construction, mining, and agriculture. As businesses strive to enhance productivity and minimize downtime, understanding the nuances of hydraulic pump selection becomes paramount. Implementing best practices in this area not only supports the achievement of performance goals but also helps in navigating the complexities associated with different pump types and applications. In this blog, we will explore five essential practices that will guide you in making informed choices when it comes to hydraulic pumps for your business.

Understanding the Different Types of Hydraulic Pumps and Their Applications in Industries

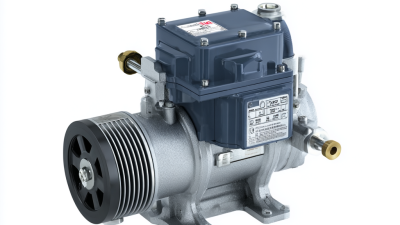

When selecting hydraulic pumps for industrial applications, it's crucial to understand the various types available and their specific uses. Hydraulic pumps can generally be categorized into gear pumps, piston pumps, and vane pumps, each tailored for different operational demands. According to a report by Research and Markets, the global hydraulic pumps market is anticipated to reach $14.3 billion by 2025, demonstrating the growing reliance on these systems across industries such as construction, agriculture, and manufacturing.

Gear pumps are often favored for their simplicity and are ideal for low-viscosity fluids. They provide a steady flow and are commonly employed in applications like hydraulic forklifts. Conversely, piston pumps offer higher efficiency and greater pressure capabilities, making them suitable for heavy-duty applications in sectors such as mining and oil exploration. The versatility of vane pumps, which can handle both low and high-pressure situations, makes them suitable for a wide range of applications, including automotive and chemical processing. Understanding these distinctions not only aids in selecting the right pump but also optimizes operational efficiency, ultimately leading to significant cost savings in industrial processes.

Hydraulic Pump Types and Their Applications

Key Performance Indicators for Selecting Hydraulic Pumps: Flow Rate, Pressure, and Efficiency

When selecting hydraulic pumps for your business, understanding key performance indicators (KPIs) is crucial in ensuring optimal efficiency and productivity. Three primary KPIs to consider are flow rate, pressure, and efficiency.

The flow rate determines the volume of fluid a pump can move within a given time, which is vital for applications that require consistent delivery of liquid. In industrial settings, matching the flow rate to your system's requirements can significantly impact operational performance.

The flow rate determines the volume of fluid a pump can move within a given time, which is vital for applications that require consistent delivery of liquid. In industrial settings, matching the flow rate to your system's requirements can significantly impact operational performance.

Pressure is another critical factor, as it influences the pump's ability to overcome system resistance and deliver fluid effectively. High pressure can be essential for applications requiring the transport of liquids through narrow passages or against gravity. Furthermore, efficiency relates to the power consumption involved in pumping fluids. Recent research has shown that optimizing blade loading in multi-stage centrifugal pumps can lead to substantial efficiency improvements. By focusing on these KPIs during the selection process, businesses can not only enhance performance but also reduce energy costs and improve overall system reliability.

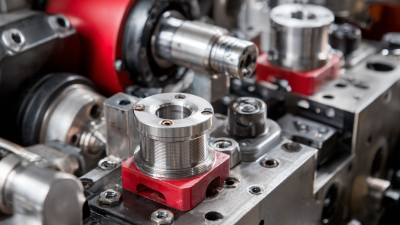

The Importance of Material Selection in Hydraulic Pump Durability and Performance

When selecting hydraulic pumps for your business, one of the most critical factors to consider is the material selection, which directly impacts both durability and performance.

High-pressure pumps, in particular, demand materials that can withstand extreme conditions while maintaining structural integrity. A comparative analysis of various structural materials reveals that advanced lightweight composites are emerging as a popular choice.

These materials offer not only weight savings but also enhanced resistance to wear and corrosion, which can significantly extend the lifespan of the pump components.

Additionally, the innovations in manufacturing technologies for these composite materials have made them more accessible and economical. The integration of lightweight structures in hydraulic pump design allows for more efficient energy use, thereby optimizing overall pump performance. As businesses increasingly prioritize sustainability, leveraging these advanced materials can provide a competitive edge, ensuring effective operational performance while reducing environmental impact. The comprehensive approach to material selection, therefore, plays a pivotal role in enhancing the reliability and efficiency of hydraulic systems in various industries.

Assessing the Total Cost of Ownership for Hydraulic Pumps: Beyond Initial Purchase Price

When selecting hydraulic pumps for your business, considering the total cost of ownership (TCO) is paramount. While initial purchase price often takes center stage, ongoing costs can substantially influence the overall financial viability of your investment. A report by the Hydraulic Institute indicates that energy costs can account for nearly 30% of a pump's total lifecycle cost, emphasizing the importance of energy-efficient models. By choosing pumps that maximize efficiency, businesses can significantly reduce their total energy expenditures over time.

Maintenance and operational expenses also play crucial roles in determining TCO. According to a study by the American Society of Mechanical Engineers, poorly maintained hydraulic systems can incur costs that exceed initial purchase prices threefold over their operational life. Investing in high-quality pumps designed for reliability can lead to reduced maintenance needs and fewer breakdowns, translating to lower costs and higher productivity. Furthermore, incorporating predictive maintenance technologies can help anticipate issues before they result in costly downtime, aligning with modern industry practices that prioritize long-term savings and efficiency.

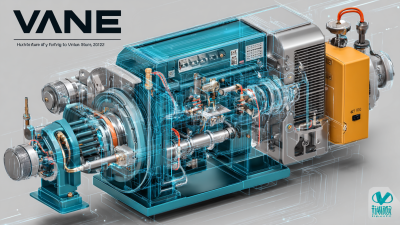

Innovative Technologies in Hydraulic Pumps: How Smart Features Improve Operational Efficiency

Innovative technologies are reshaping the landscape of hydraulic pumps, making them essential for enhancing operational efficiency in various industries. The integration of smart features, such as real-time monitoring and predictive maintenance, allows businesses to optimize performance and reduce downtime. These advancements not only contribute to increased productivity but also play a crucial role in promoting sustainability. For instance, energy-efficient pumps can significantly lower energy consumption, aligning with global efforts towards a more sustainable future.

Furthermore, the industrial pump market is experiencing a transformation driven by cutting-edge technological advancements. Companies are increasingly adopting automation and digitalization, which streamline operations and improve safety. In addition to these innovations, the integration of smart water management systems is revolutionizing sectors like agriculture and urban planning. By effectively managing resources, these technologies help in minimizing waste and enhancing overall efficiency, proving that hydraulic pumps are indeed hidden champions of energy efficiency and sustainability.

Related Posts

-

7 Reasons Why Best Hydraulic Pump Parts Enhance Equipment Efficiency

-

Global Buyers Choose Chinese Made Pressure Pumps for Superior Quality Upgrades

-

Exploring the Versatility and Applications of the Best Hydraulic Pump Motors

-

Ultimate Guide to Comparing the Best Hydraulic Vane Pumps for Global Buyers

-

Understanding the Features of the Best Piston Pump for Global Buyers

-

Navigating the Future of Vane Pumps in 2025 Top Technology Trends and How to Adapt Your Supply Chain