- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

7 Reasons Why the Best High Pressure Pump is Essential for Your Industrial Operations

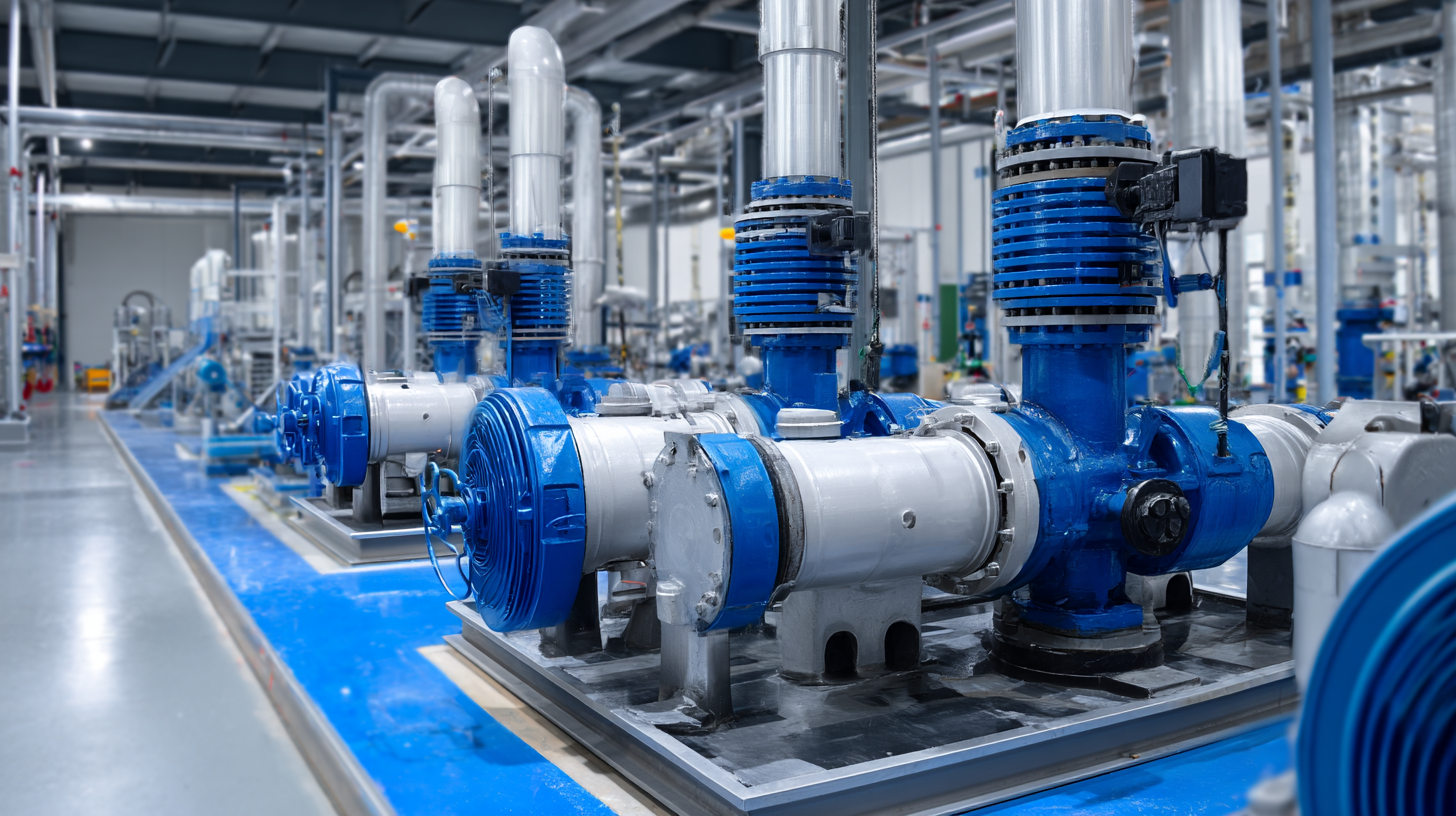

In today's competitive industrial landscape, the significance of efficient and reliable equipment cannot be overstated. Among the crucial components that contribute to operational success is the High Pressure Pump, which plays a pivotal role across various sectors, from manufacturing to oil and gas.

According to a recent report by MarketsandMarkets, the global high pressure pump market is projected to reach USD 5.9 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth highlights the increasing recognition of high pressure pumps in enhancing productivity, optimizing resource consumption, and addressing challenges such as corrosion and wear in harsh environments.

As industries strive to maintain optimal performance and reduce downtime, understanding the reasons behind the necessity of the best high pressure pump becomes essential for ensuring streamlined operations and sustainable growth.

The Role of High Pressure Pumps in Enhancing Operational Efficiency

High pressure pumps play a pivotal role in enhancing operational efficiency across various industrial sectors. According to a report from the Fluid Power Industrial Association, the use of high pressure pumps can increase the overall system performance by up to 30%. This is particularly crucial in industries such as oil and gas, where efficient fluid transfer directly impacts production timelines and cost management. By delivering fluids at higher pressures, these pumps not only optimize flow rates but also reduce the likelihood of downtime due to equipment failures, making them indispensable in maintaining operational continuity.

Moreover, high pressure pumps contribute significantly to energy savings, a key factor in today’s cost-conscious environment. According to a 2022 study published in the Journal of Industrial Engineering and Management, systems utilizing high pressure technology have demonstrated a reduction in energy consumption by approximately 15% over conventional pumping systems. This reduction not only lowers operational costs but also aligns with global sustainability goals by minimizing the carbon footprint associated with industrial processes. Thus, investing in high pressure pumps is not just a matter of operational efficiency but also a strategic move toward environmental responsibility and economic prudence.

Impact of High Pressure Pumps on Operational Efficiency

Key Features to Look for in a High Pressure Pump for Industrial Use

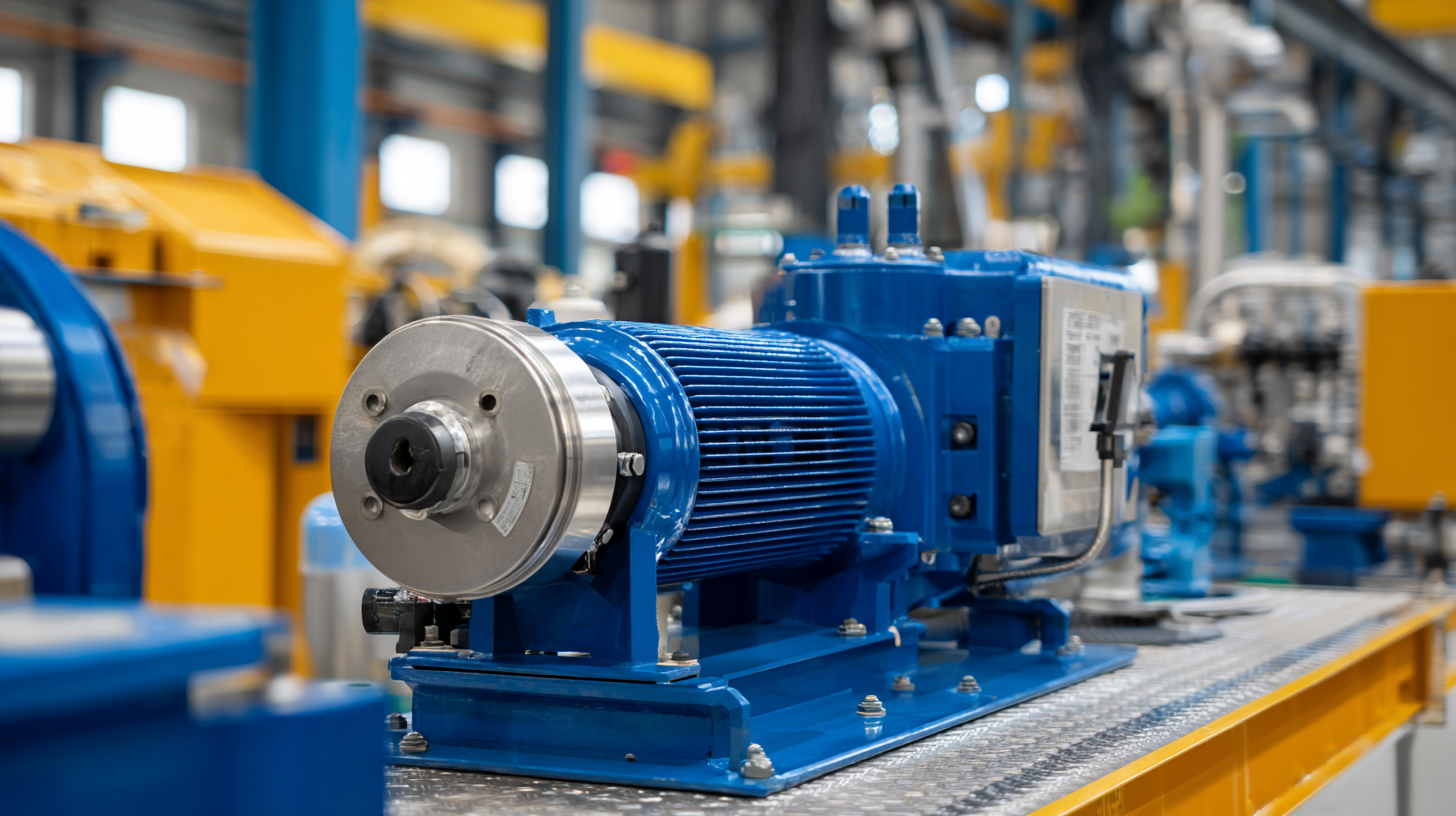

When selecting a high-pressure pump for industrial applications, certain key features can significantly enhance efficiency and performance. First, consider the pump's pressure rating, as it dictates the maximum pressure the system can achieve. High-pressure pumps can typically reach up to several thousand PSI, making them ideal for tasks such as cleaning, spraying, and transporting fluids. A reliable pump should also offer consistent pressure delivery, ensuring that operations run smoothly without interruptions.

Another critical feature is the pump's construction material. Pumps made from durable materials, such as stainless steel or high-grade alloys, offer greater resistance to wear and corrosion, which is particularly important in demanding industrial environments. Additionally, the pump's flow rate is essential; it determines how much fluid can be moved in a specific time frame, influencing overall operational efficiency. Lastly, consider the ease of maintenance and repairability. A pump designed for straightforward servicing can reduce downtime and extend service life, ultimately saving costs and enhancing productivity in industrial operations.

7 Reasons Why the Best High Pressure Pump is Essential for Your Industrial Operations - Key Features to Look for in a High Pressure Pump for Industrial Use

| Feature | Importance | Impact on Efficiency | Maintenance Requirements |

|---|---|---|---|

| High Pressure Capability | Enables operations requiring high fluid dynamics | Increases throughput and operational capacity | Regular checks for pressure settings needed |

| Durability | Reduces downtime and maintenance costs | Ensures consistent performance over time | Periodic inspections recommended |

| Energy Efficiency | Lowers operational costs | Enhances profitability by reducing energy consumption | Minimal maintenance; check for wear and tear |

| Safety Features | Protects staff and equipment | Prevents accidents and operational interruptions | Regular safety audits recommended |

| Versatility | Accommodates various industrial applications | Increases flexibility in operations | Lower maintenance frequency |

| Compact Design | Saves space in industrial setups | Maximizes space efficiency | Infrequent checks needed |

| Advanced Control Systems | Enhances operation monitoring | Improves reliability and responsiveness | Requires periodic software updates |

Cost-Benefit Analysis: Investing in a Quality High Pressure Pump

Investing in a quality high pressure pump can yield significant long-term cost savings for industrial operations. Unlike cheaper alternatives that might require frequent repairs or replacements, a well-engineered high pressure pump offers reliability and durability. This means less downtime and lower maintenance costs, allowing your business to maintain consistent productivity without the interruptions that often accompany subpar equipment. The initial investment may be higher, but the reduced operational costs and extended lifespan of quality pumps make them a wise financial choice.

Additionally, a high pressure pump can enhance efficiency across various processes, such as cleaning, mixing, and fluid transportation. By optimizing these operations, businesses can not only save on labor costs but also achieve better output quality. The enhanced performance can translate into an improved product, leading to higher customer satisfaction and increased sales. Therefore, when conducting a cost-benefit analysis, it becomes evident that the advantages of investing in a premium high pressure pump far outweigh the initial expenditure, reinforcing its essential role in industrial success.

Impact of High Pressure Pumps on Equipment Longevity and Maintenance

High pressure pumps play a crucial role in enhancing equipment longevity and reducing maintenance costs in industrial operations. By delivering fluids at high pressure, these pumps ensure that processes are efficient and effective, minimizing wear and tear on machinery. This efficiency translates to less stress on critical components, thereby extending their life span. When pumps operate at optimal pressure levels, they reduce the chances of leaks and overexertion, which can lead to expensive repairs and downtime.

High pressure pumps play a crucial role in enhancing equipment longevity and reducing maintenance costs in industrial operations. By delivering fluids at high pressure, these pumps ensure that processes are efficient and effective, minimizing wear and tear on machinery. This efficiency translates to less stress on critical components, thereby extending their life span. When pumps operate at optimal pressure levels, they reduce the chances of leaks and overexertion, which can lead to expensive repairs and downtime.

Moreover, the impact of high pressure pumps on maintenance cannot be overstated. Regular maintenance is essential in industrial settings, and high pressure pumps can simplify this process. When integrated into a system, they can help maintain consistent flow rates and pressure levels, as well as prevent blockages that could compromise equipment functionality. This reliability allows maintenance teams to focus on proactive rather than reactive strategies, ultimately fostering a more productive environment. By investing in high pressure pumps, industries can significantly enhance their operational efficiency and reduce the frequency of maintenance interventions.

Trends Shaping the Future of Industrial High Pressure Pump Technology

The evolution of industrial high-pressure pump technology is being shaped by several key trends that are revolutionizing operations across various sectors. As industries pivot towards sustainability, the demand for energy-efficient pumps has grown significantly. Utilizing advanced materials and design innovations, manufacturers are developing pumps that not only maximize efficiency but also minimize environmental impact. This trend aligns with global efforts to reduce carbon footprints and comply with stringent regulations.

Another significant trend is the integration of smart technology. The advent of IoT and automation in high-pressure pump systems allows for real-time monitoring and predictive maintenance. This capability enhances operational reliability and reduces downtime, ensuring that businesses can maintain seamless production processes. Coupled with data analytics, industries can now gain valuable insights into performance metrics, enabling better decision-making.

Tip: When upgrading to a new high-pressure pump, consider models that integrate smart technology for improved monitoring and efficiency. Also, evaluate the long-term sustainability of materials used in pump manufacturing to align with green initiatives in your operations. Investing in energy-efficient pumps can lead to cost savings and a competitive edge in the market, making it a win-win for your business.